Understanding Shipment Packing Profile

What is a Shipment Packing Profile?

A Shipment Packing Profile in Canary7 defines how packing tasks are handled within your warehouse. It determines:

✅ Which packing jobs a user can access

✅ How the packing process functions

✅ What verification steps are required to complete packing

These profiles are crucial for ensuring that packing is streamlined, accurate, and tailored to your operational needs.

🔍 Accessing Shipment Packing Profiles

You can access the module in two ways:

Use the Search Bar in the Navigation Menu and type "Shipment Packing Profile"

Or go to:

Configuration → Shipment Profile Setup → Shipment Packing Profile

➕ Adding a Shipment Packing Profile

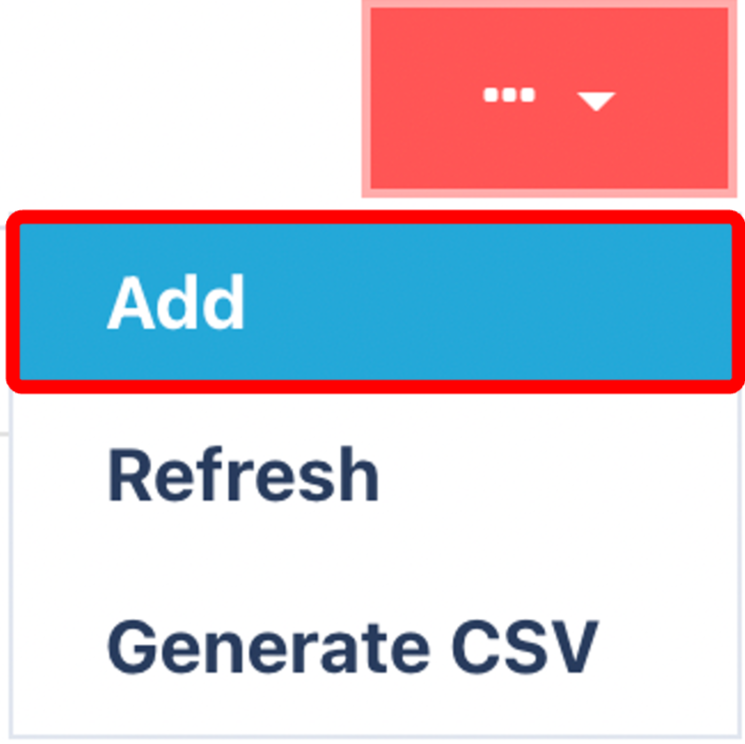

Click on the Red Action Button , this will bring up a drop-down menu, and select "Add"

, this will bring up a drop-down menu, and select "Add"

🧾 General Tab

Complete the required fields under the General Tab.

| Field | Description |

|---|---|

| Name | Name of the Packing Profile |

| Initiation Method | Choose between Container or Location |

| Packing Location | This is always set as User Defined e.g. PAC-01 |

| Blind Packing | Enable to hide item details during packing (e.g. item name or quantity) |

| Auto Generate Pack To Container ID | Enable to automatically generate container IDs during the packing process |

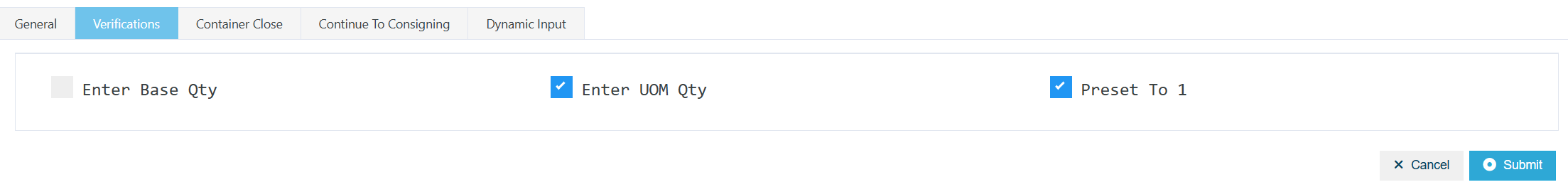

✅ Verifications Tab

Customise how the user interacts with each packing task:

| Verification | Description |

|---|---|

| Enter Base Qty | Prompts the user to enter the base quantity manually |

| Enter UOM Qty | Requires the user to enter quantity by Unit of Measure |

| Preset to 1 | Auto-sets quantity to 1 — ideal for scan-by-scan environments |

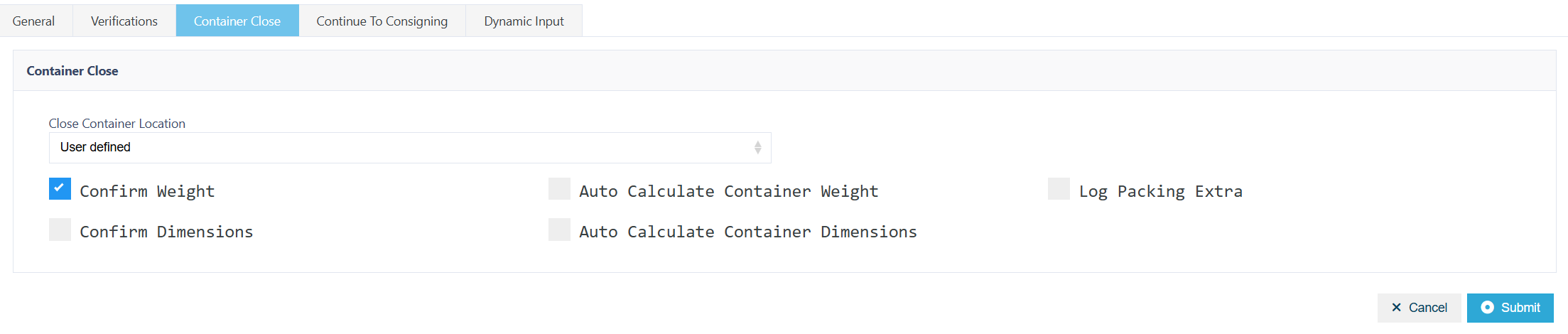

📦 Container Close

📦 Container Close Options

Decide what happens when a container is ready to be closed:

| Option | Description |

|---|---|

| Confirm Weight | Require users to input the final weight manually |

| Confirm Dimensions | Ask for container dimensions before closure |

| Auto Calculate Container Weight | System calculates weight based on packed contents |

| Auto Calculate Container Dimensions | Automatically derives container dimensions |

| Log Packing Extra | Let users record exceptions, notes, or issues during packing |

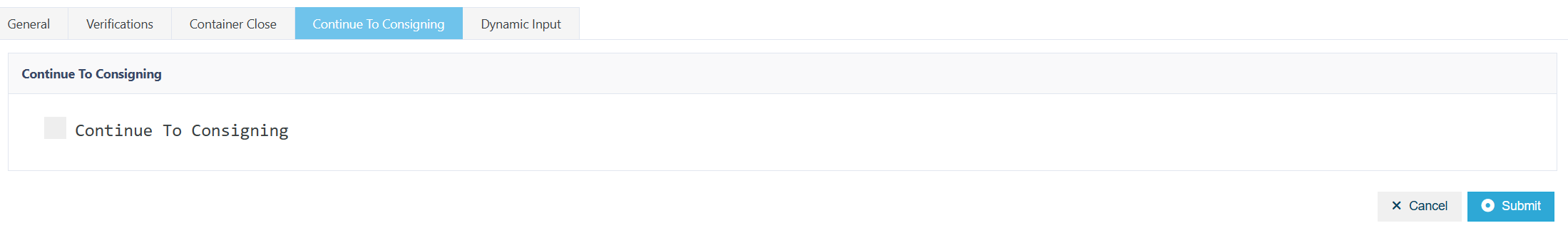

🚚 Continue to Consigning

Enable this setting to automatically direct users to the Consigning screen once packing is complete—great for streamlining outbound processes.

Enable this setting to automatically direct users to the Consigning screen once packing is complete—great for streamlining outbound processes.

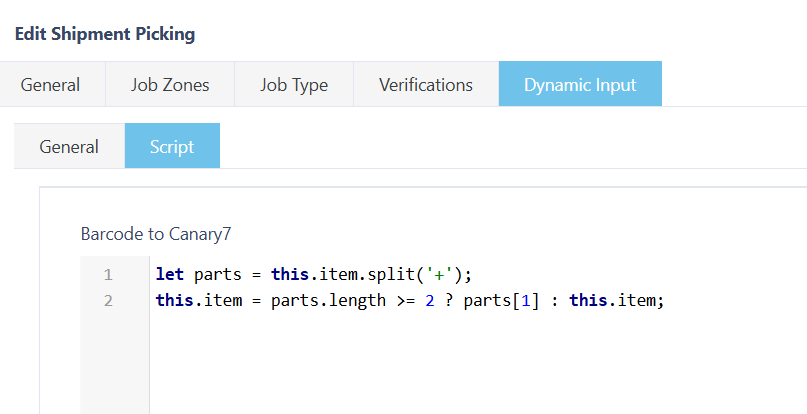

🧠 Dynamic Input

Dynamic Input enables the system to interpret barcode scans in real-time using flexible parsing scripts.

📌 Use Cases

Standardise Barcode Formats

Handle barcodes from multiple suppliers by normalising structures.Remove Unwanted Characters

Strip out prefixes, suffixes, or non-essential characters.Extract Relevant Data

Parse complex barcodes and isolate only the required details (e.g., SKU, batch, expiry).Support Multiple Symbologies

Convert different barcode types into a format Canary7 understands.

This gives you greater control over scanning workflows and improves compatibility across suppliers and products.

Once you have selected and entered the required fields, click on the submit button.png) to add.

to add.