Understanding Consigning

What is Consigning?

The Consignment screen in Canary7 is a critical step that occurs after packing. After packing is complete, the consignment screen is used to review and finalise all shipping documentation before the carrier collects the outbound shipment.

Key Functions:

Documentation Finalisation:

The screen enables users to print all necessary shipping documents, including:- Consignment labels

- Delivery notes

- Commercial invoices

- Packing slips

Carrier Updates:

Users have the option to update the consignment carrier if changes are required. This function allows you to:- Assign a different Carrier

- Update the Carrier Service

- Modify the Load Number

Creating Consignment Pieces:

Definition:

A consignment piece typically corresponds to an individual container (such as a box or pallet) that forms part of the shipment.Purpose:

Creating consignment pieces ensures that the system can print separate consignment labels for each piece. These labels detail the sequence (e.g., Piece 1 of 4, Piece 2 of 4, etc.), which improves tracking and accountability of each shipment component.

This structured process helps guarantee that all shipping details are accurately documented and that any necessary adjustments to carrier information are easily managed before the shipment leaves the facility.

Within the Navigation menu, click on the search bar, type ''Consigning'' and click "Consigning". Consigning is also in Shipping > Consigning.

🔧 Consigning Methods

Canary7 offers two consignment methods:

1. Automatic Consignment

The system automatically creates consignment pieces based on the number of Pack From containers.

Labels are generated accordingly without further input from the user.

2. Manual Consignment

The user manually defines the number of consignment pieces to create.

Suitable when a specific structure or number of labels is required.

✳️ New Feature: Piece Creation Options

When Manual Consignment is selected, a new dropdown option appears in the Consigning Profile, under Piece Creation. It includes:

- Weight Per Piece (existing functionality)

Users create pieces one-by-one.

The weight is defined manually for each piece.

- Pieces Per Consignment (new)

Users are prompted to input how many pieces they wish to create.

The system will:

Create the specified number of pieces

Evenly distribute the total consignment weight across all pieces

This feature allows for faster and more consistent consignment creation when the number of pieces is known in advance.

🛠️ How to Use Consigning

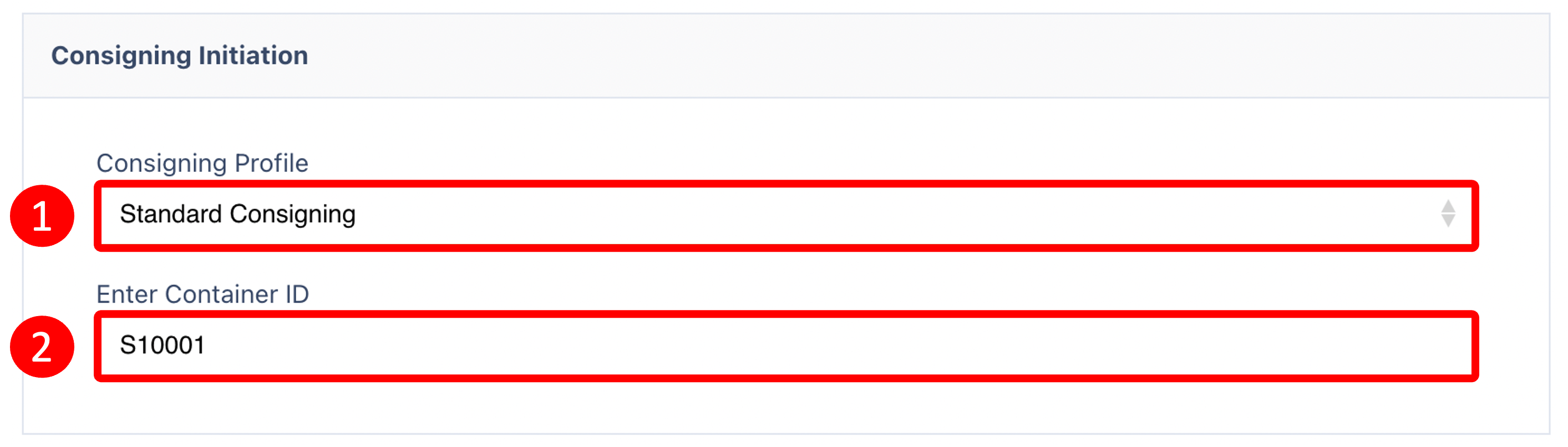

Consigning Initiation

1. Start Consigning

Select your Consigning Profile

Enter the Container I.D or Shipment Number

Click Next

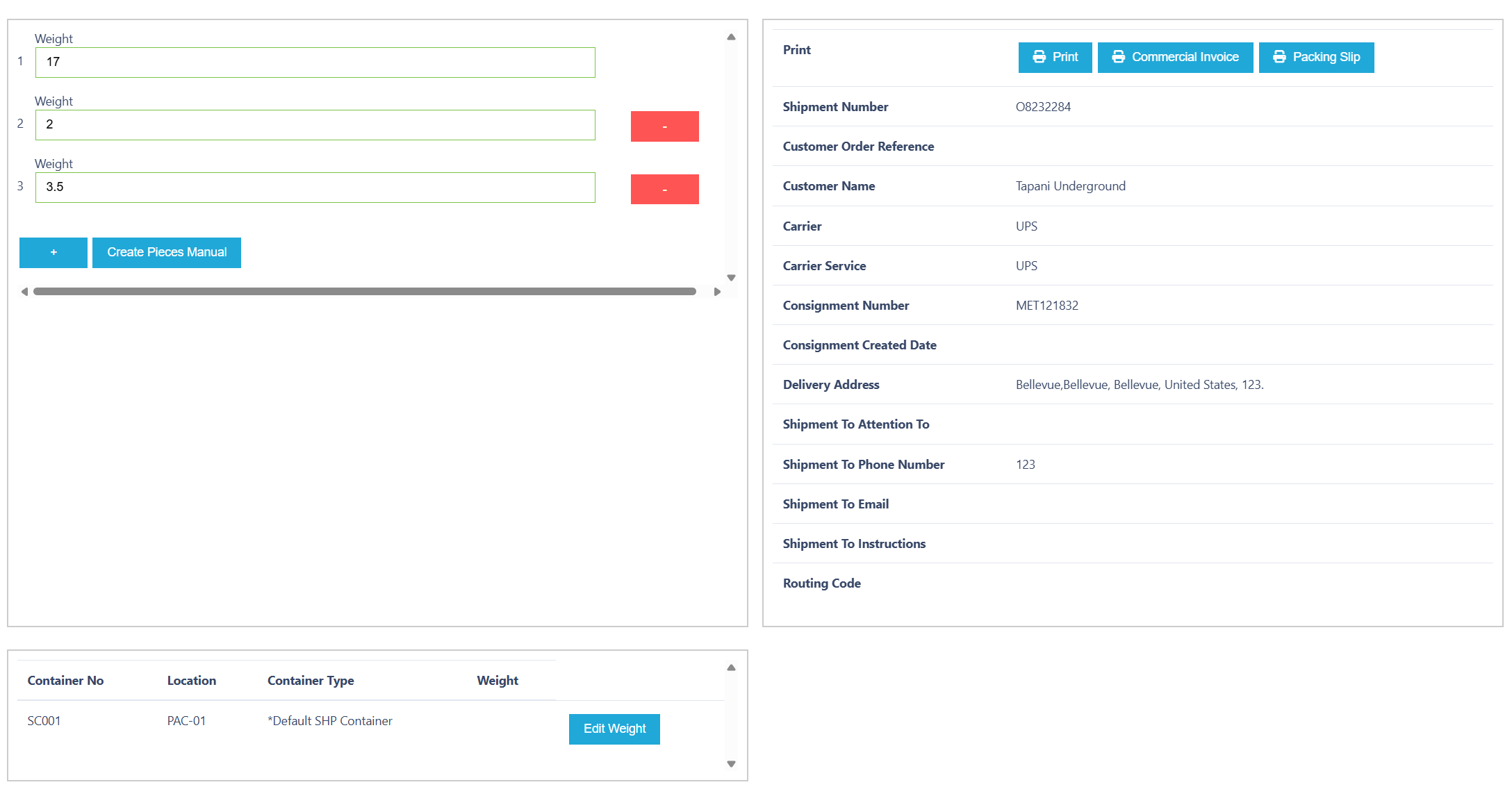

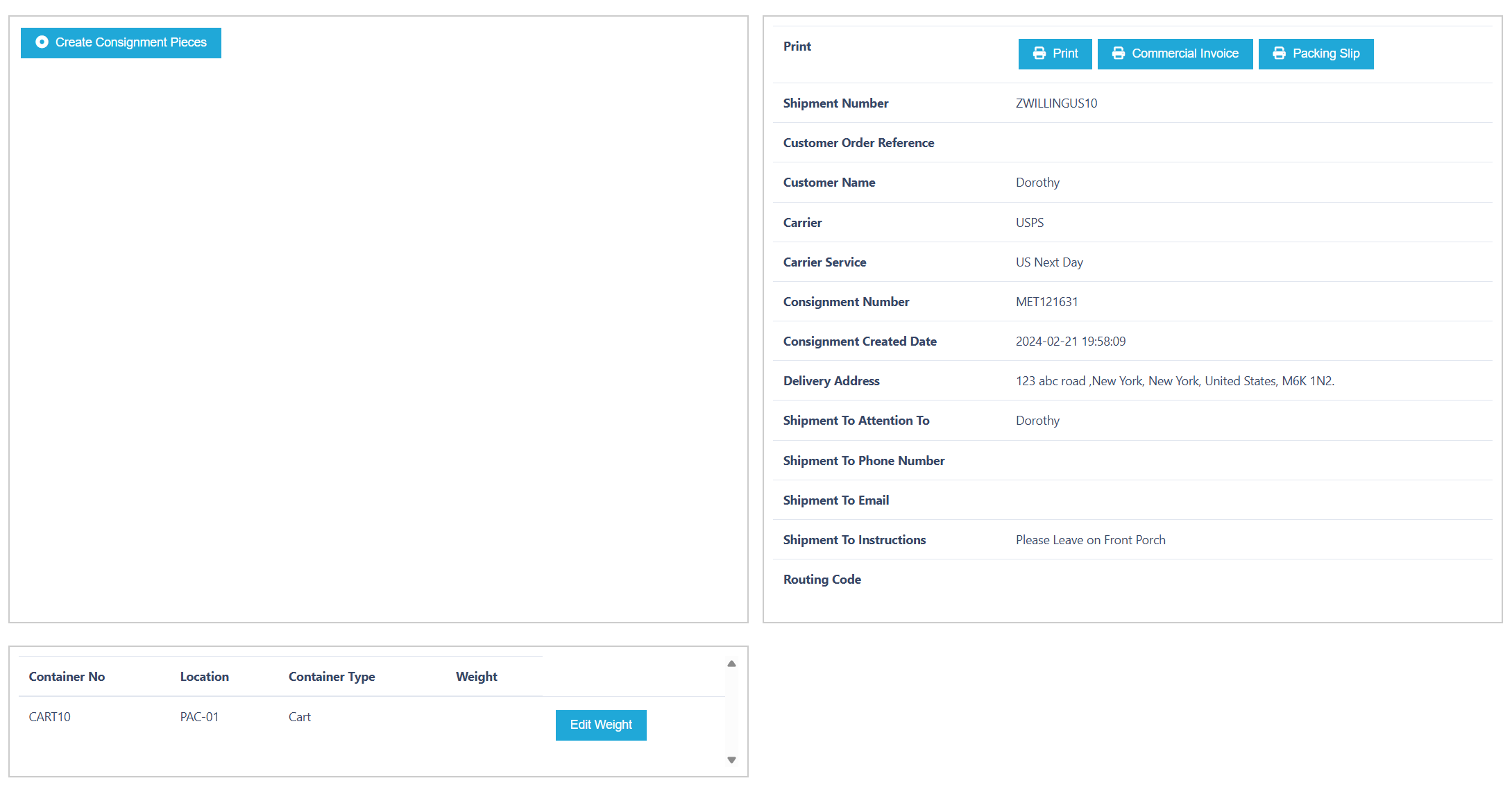

Create your required number of Consignment Pieces

If using Manual Consignment:

Click Create Consignment Pieces, depending on your Piece Creation method (Weight Per Piece or Pieces Per Consignment) this will function differently.

If Pieces Per Consignment is selected, input how many pieces you want to create - The system will then create that number of containers and divide the total weight between them

If Weight Per Piece is selected, create as many pieces as you need, and specify the weight of each (below).

If using Automatic Consignment:

The system automatically determines the number of consignment pieces based on how many ‘Pack From’ containers are associated with the shipment

No manual input is required for number of pieces

The system generates:

One piece per pack container

Consignment labels for each piece (e.g., “Piece 1 of 3”, “Piece 2 of 3”)

This method is ideal for high-volume or standardised shipments where each container naturally represents a consignment piece.

Enter Tracking number (If required)

![]()

Enter the Tracking Number

Click Confirm Tracking Number

The system will:

Automatically print the required number of Consignment Labels (1 per piece)

Move the shipment to Awaiting Dispatch Confirmation

🛈 Note: This step is often skipped or automated depending on your carrier integration. In most cases, the system will bypass this screen and print the label automatically once the shipment reaches this stage.

🖨️ If a consignment label fails to print (e.g. due to a hardware issue), you can manually reprint it:

Go to Shipping > Consignment Enquiry

Locate the relevant consignment

Click Reprint to reissue the documentation