📋 Understanding Replenishment Template

What is a Replenishment Template?

A Replenishment Template defines the rules and logic for generating replenishment jobs. It determines when, where, and how inventory should be replenished to maintain optimal stock levels in picking or forward locations.

Replenishment Templates are typically triggered as part of automated planning or manually by users. Once a template is run, it produces replenishment jobs that can be processed by operatives on the execution screen.

Templates are divided into two core tabs:

Demand Tab → Defines when replenishment is needed and for which items.

Supply Tab → Defines how the demand is fulfilled and where inventory is sourced from.

🔄 How Replenishment Components Work Together

| Component | Purpose |

|---|---|

| Replenishment Profile | Filters which jobs are shown to users on the Replenishment Execution screen (based on zones, job types, and verification rules). |

| Replenishment Template (Plan) | Defines demand triggers and supply sourcing rules that generate replenishment jobs. |

| Replenishment Job Creation (Job Creation Master) | Groups and orders the jobs generated by the template to optimise execution. |

📥 Demand Tab

The Demand tab is now split into two sections: Requirement and Target.

🧾 Requirement Section

| Field | Description |

|---|---|

| Demand | Select one of the following replenishment triggers: • Permanent Location Capacity – Triggers when inventory in fixed locations falls below a minimum level. • Pool and Wave by Quantity – Used when a Wave fails due to stock shortages; user manually triggers replenishment by running the plan. • Pool by Quantity – Based on pre-defined thresholds in Pool locations. • Pool by Optimal UOM – Suggests replenishment based on ideal units of measure. |

| Item Selection | Defines which items are eligible for replenishment. See: [Item Selection Guide] |

| Shipment Selection | (Optional) Used to filter replenishment demand based on shipment criteria. Useful for wave-related replenishment needs. |

🎯 Target Section

| Field | Description |

|---|---|

| Target Location Selection | Defines which locations require replenishment. For Permanent Location Capacity, this usually includes forward pick locations. |

| Locating Rule | Used to determine how the system selects a specific location when there are multiple options. 🔹 Note: This is not available when using Permanent Location Capacity. |

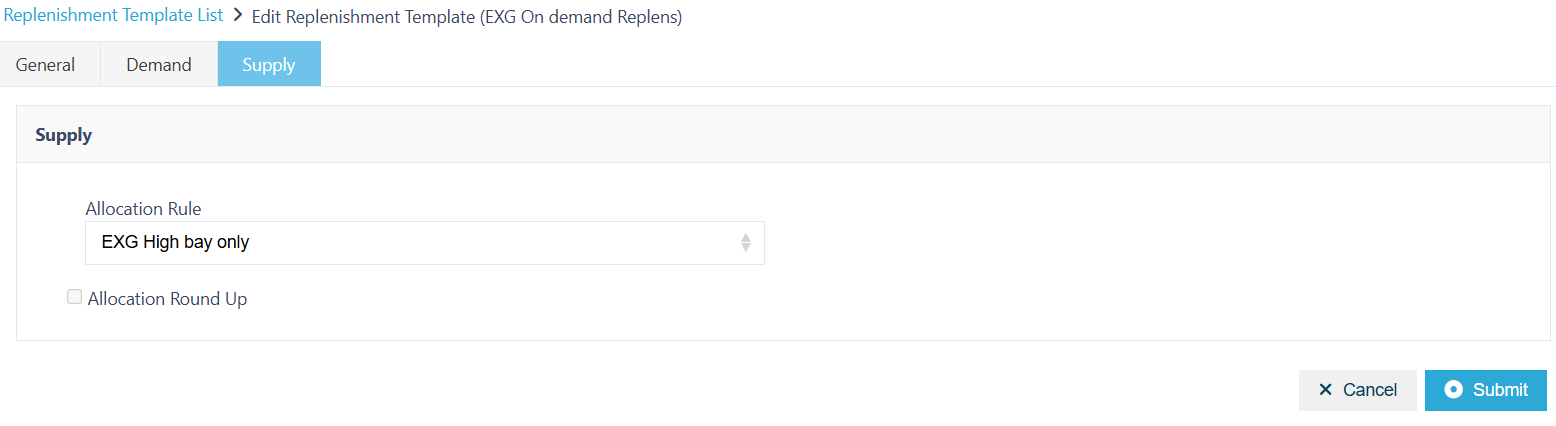

📦 Supply Tab

This tab defines how inventory is sourced to fulfil the replenishment demand.

| Field | Description |

|---|---|

| Allocation Rule | Selects the allocation strategy (e.g., FIFO, FEFO) for picking stock from source locations. |

| Allocation Round Up | Determines if replenishment quantities should be rounded up (e.g., to full cases). • Yes – Rounds quantities up to the nearest case/UOM. • No – Picks exact required quantity. |

🧭 Accessing Replenishment Template

You can access Replenishment Templates in two ways:

From the Navigation Menu, search for "Replenishment Template".

Or navigate to:

Configuration > Functional Area Setup > Replenishment Setup > Replenishment Template

🛠️ Step-by-Step: Configuring the Demand and Supply Tabs

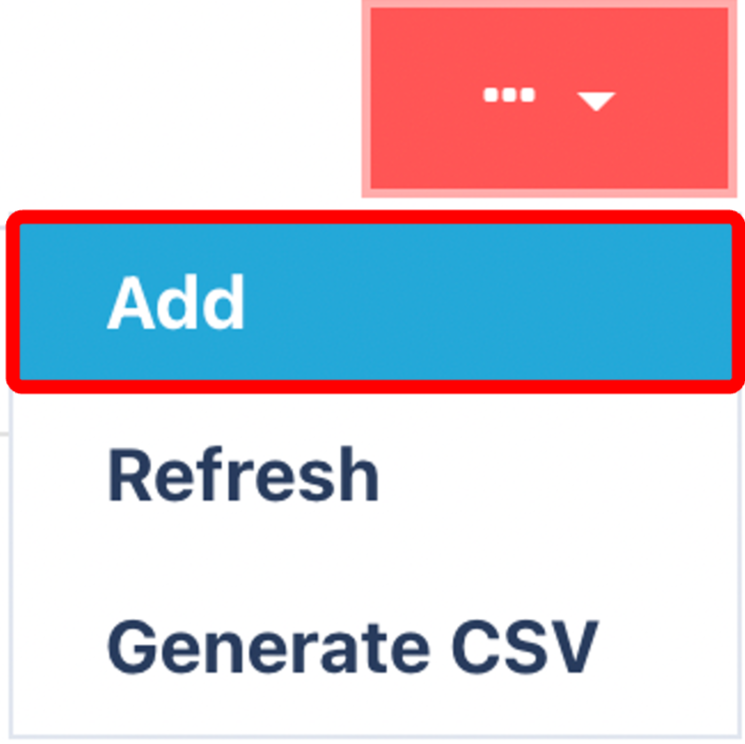

Click on the Red Action Button , this will bring up a drop-down menu, and select "Add"

, this will bring up a drop-down menu, and select "Add"

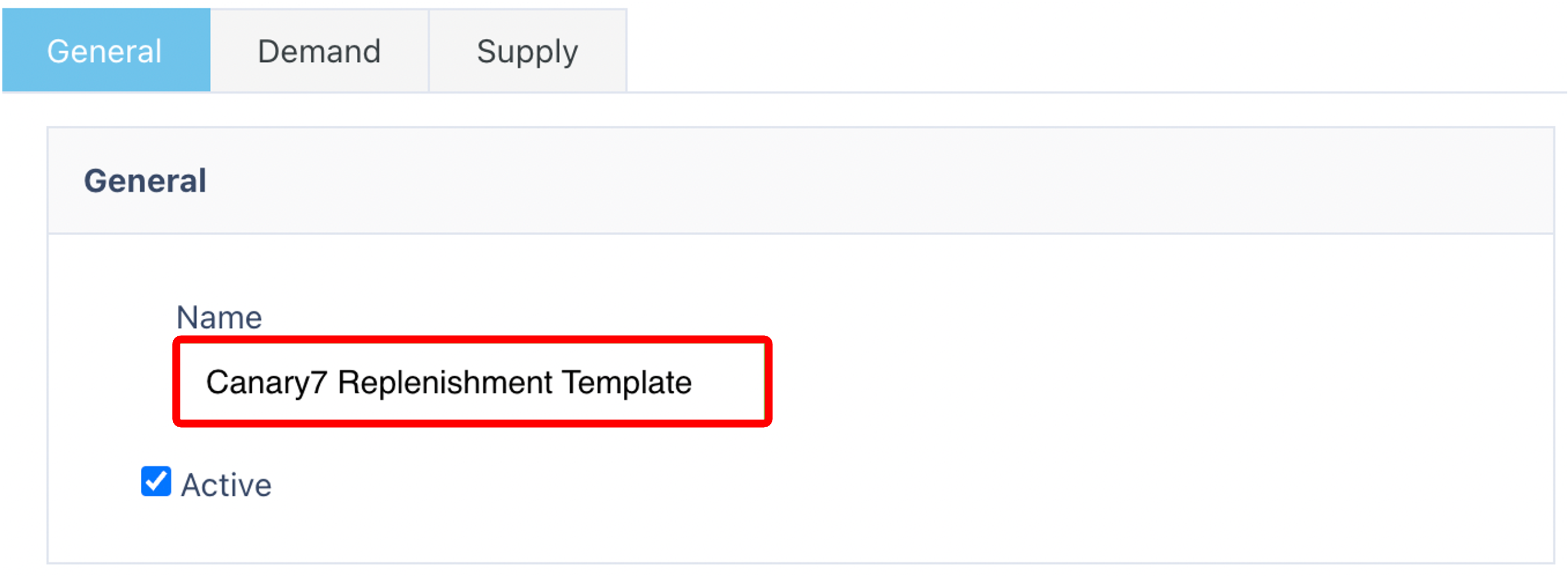

Name your Template

Enter the name of your Template and ensure that is checked.

is checked.

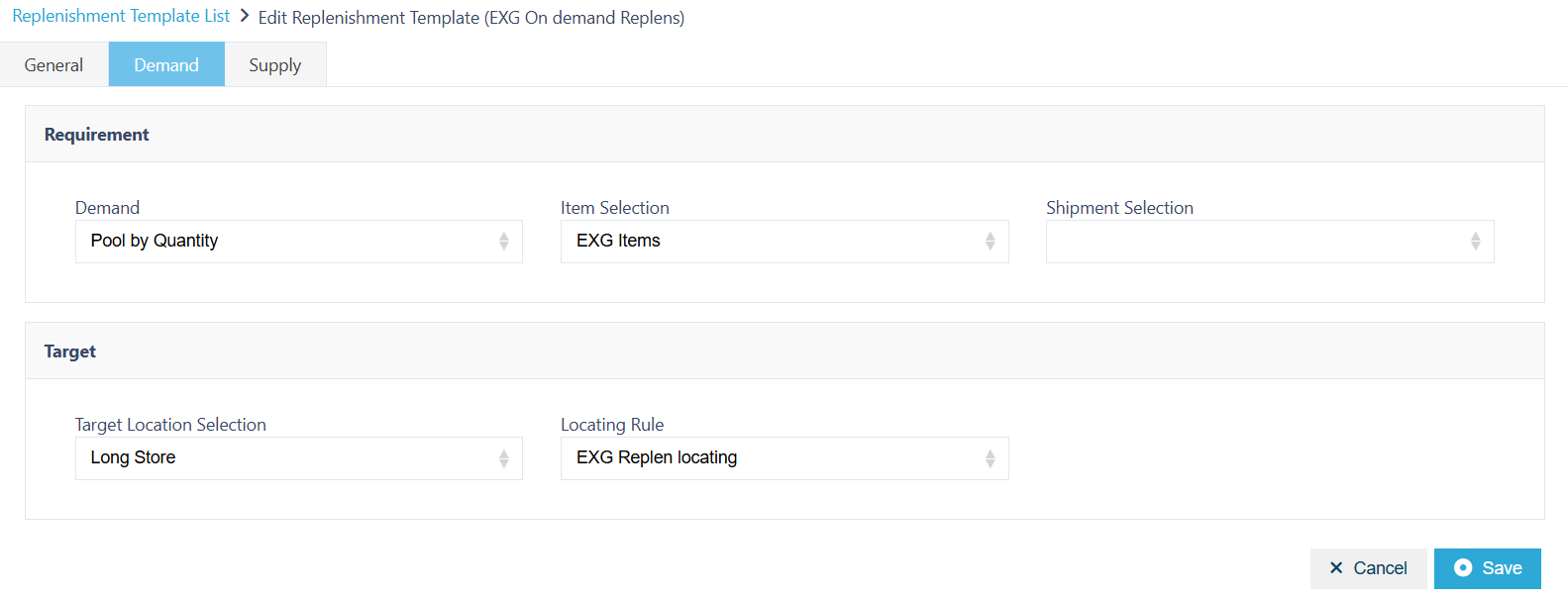

📥 Demand Tab Configuration

➤ Requirement Section

Select a Demand Type

From the dropdown, choose one of the following options:Permanent Location Capacity

Pool and Wave by Quantity

Pool by Quantity

Pool by Optimal UOM

Add an Item Selection

Click Add or Select to choose an existing Item Selection.This defines which items should be considered for replenishment.

(Optional) Add a Shipment Selection

If you're using a pool or wave-based demand type, you can narrow the focus by selecting specific shipments.

➤ Target Section

Add a Target Location Selection

Choose or create a Location Selection to define which warehouse locations should be replenished.(If Applicable) Add a Locating Rule

Only required when using Pool-based demand types.

Select a Locating Rule to guide how the system chooses specific destination locations within the target selection.

🚚 Supply Tab Configuration

Select an Allocation Rule

Choose the appropriate Allocation Rule (e.g., FIFO, FEFO) that governs how stock is picked from supply locations.Set Allocation Round Up

Choose whether to round replenishment quantities:Yes – Rounds to nearest case/UOM.

No – Uses exact required quantity.

Once all fields are complete, click Submit to save your Replenishment Template.

Once you have selected and entered the required fields, click on the submit button.png) to add.

to add.