Blind Packing

Feature Overview

Blind Packing is a process used in warehouse operations where packers do not have prior visibility into the order details. Instead of manually checking a packing list, they rely on scanning each Item as it is packed to ensure accuracy. This method is commonly implemented in Warehouse Management Systems (WMS) to enhance efficiency, reduce errors, and streamline the packing process.

Why use Blind Packing?

Blind Packing offers several advantages in warehouse operations:

Improved Accuracy – Since each item must be scanned before being packed, the risk of human error is minimised compared to manual verification methods.

Prevention of Bias & Assumptions – Packers do not assume what should be included in the shipment; scanning ensures the correct products are packed.

Increased Efficiency – Blind Packing can speed up the packing process by eliminating the need for packers to cross-check order details manually.

Supports High-Volume Operations – This method is beneficial in warehouses with automated picking systems, where items are pre-selected and delivered to the packing Station in sequence.

Reduces Training Time – New employees can quickly adapt to the process without requiring extensive product knowledge; they simply follow the scanning and packing steps.

How to Implement Blind Packing

Enabled Blind Packing on your desired Packing Profile

.png)

Navigate to Shipment Packing Profile List, and edit the desired Packing Profile. Ensure Blind Packing is enabled.

Initiate Packing

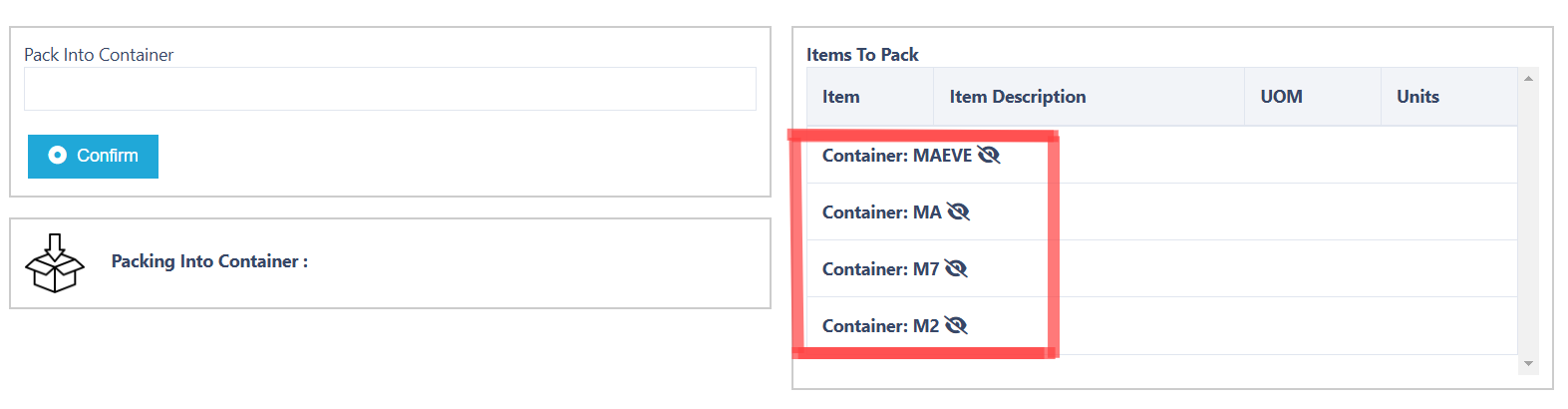

You will now be presented with the Containers that this consignment is comprised on. However, you will no longer be able to see the contents of each Container.

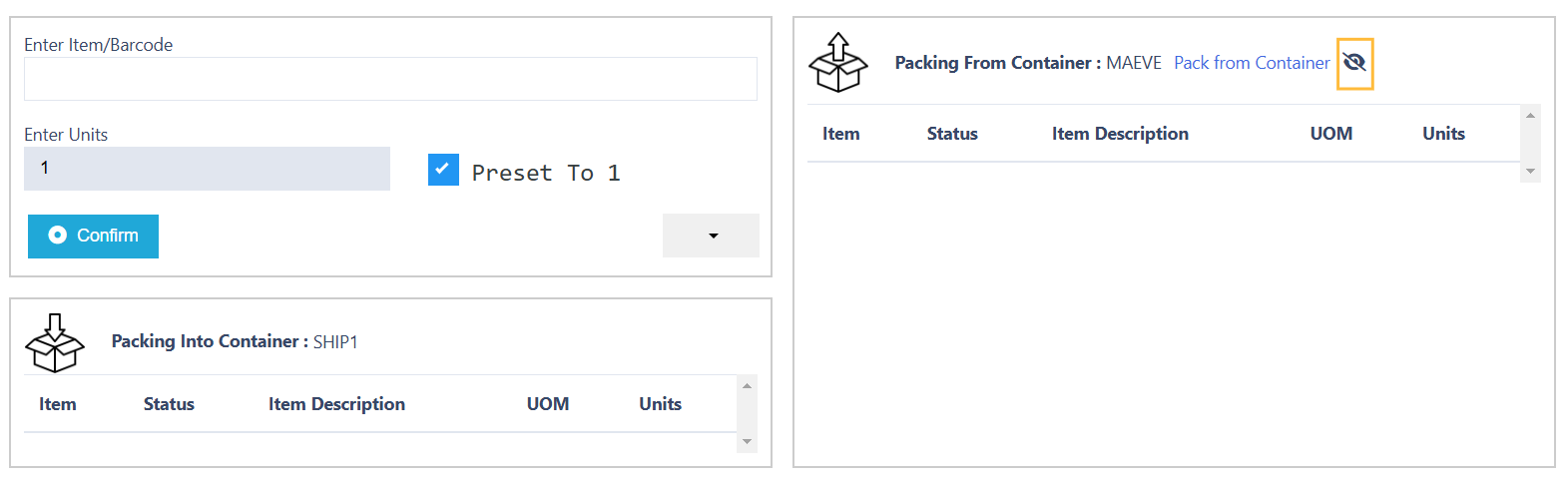

Create your Pack Into Container

You will now be asked to scan the various items within the From Container. Once all items are packed, this From Container will be Closed, and we will move onto the next one (If there are multiple). If the Eye Icon (highlighted above) is clicked, users will then see the contents of the container, a process log will be created called ‘Blind Pack Fail, as well as details of the user, timestamp, shipment number and container number.

.png)